Hazardous Leak Detection with an optical gas imaging camera can help companies meet their regulatory requirements, mitigate costs and improve safety around the work site.

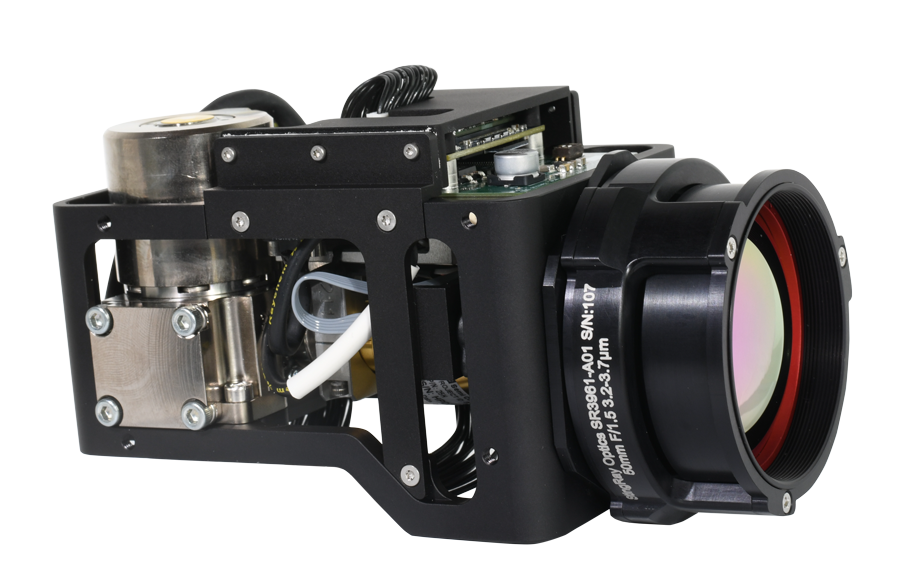

Amidst the mounting challenges posed by stringent oil and gas regulations, the Ventus OGI camera emerges as a crucial solution, aiding in the mitigation of leakage and the enhancement of line production. We partner with companies like Linkedall, Champion-X, MFE and more to build the core of optical gas imaging technology systems. By practicing leak detection and repair (LDAR), not only can you save substantial funds, but you can also safeguard your workforce from potential hazards and avoid high penalties. The high-performance, low SWaP characteristics of the core sensor we build, the Ventus OGI, is a tool aimed at preserving time for integration into a variety of platforms.

50MM Lens

VENTUS OGI

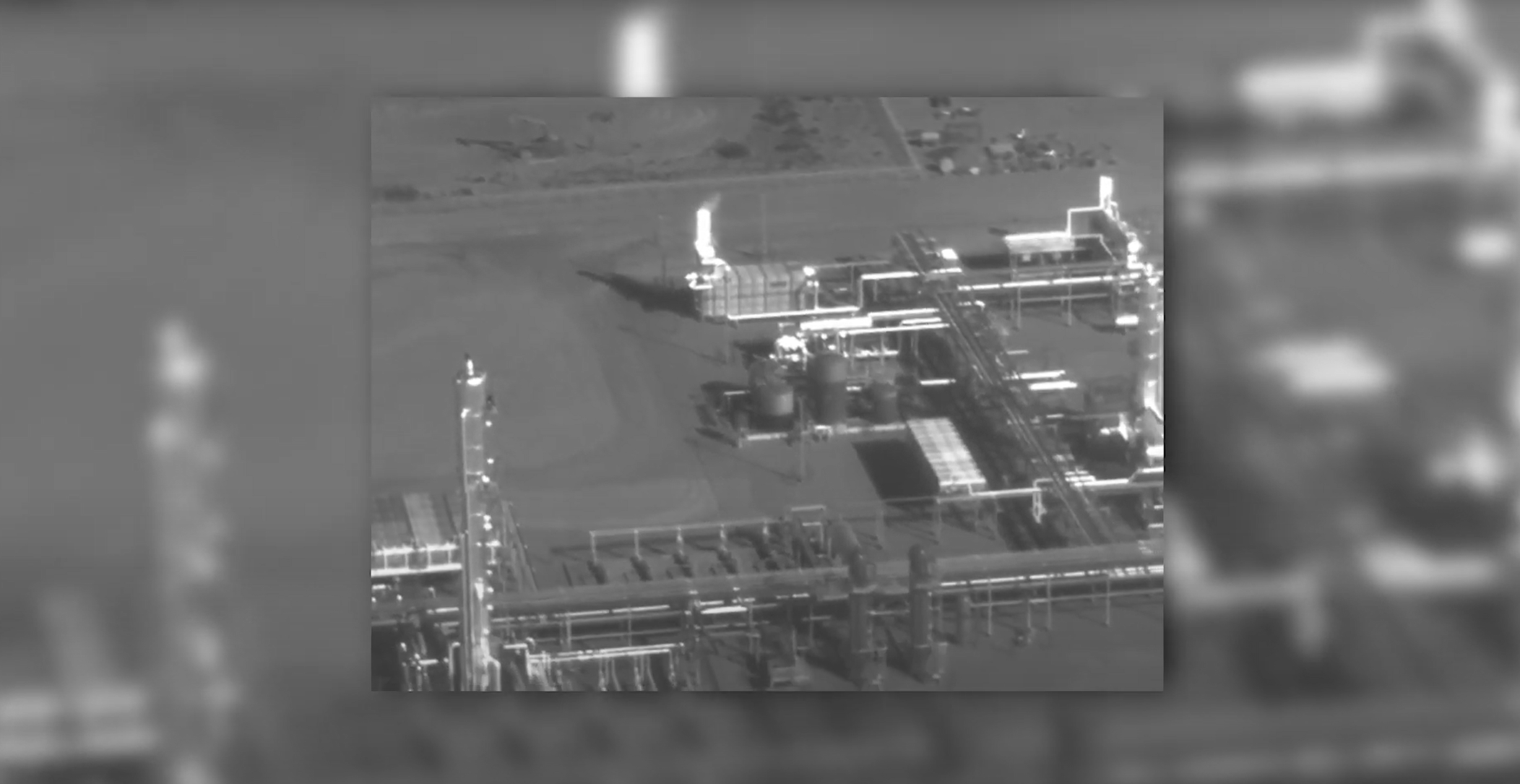

Ventus OGI 50mm 11 ° FOV optimized for longer-range leak detection applications including ground-based fixed mounted systems as well as airborne systems including fixed-wing aircraft from above 1,000+ ft. This allows you to survey large areas quickly and efficiently from a safe distance.

25MM Lens

VENTUS OGI

The Ventus OGI 25mm has 21.7 ° FOV optimized for closer-in applications where a wide field of view is ideal, including UAV/UAS, handheld units, fixed mounted and ground-based robotics applications.

Emission Compliant

The current OOOOa standard has been in place for a number of years. That OGI standard, 60 g/hr with a 50/50 mixture of methane and propane gases. Roughly 10,000 ppm. using a quarter inch orifice. The new proposed rules OOOOb and OOOOc are looking to target 17 g/hr for methane and 18.5 g/hr for butane at a distance of two meters away, also at a deltaT of around 5° centigrade at 1 meter/second. Methane “Super Emitters” are detected at 100 kg/hr and must be fixed within 10 days of being identified.

The new proposed standard that will go into place has been established by the United Nations and OGMP and is being adopted by the rest of the world. One of the things that Sierra-Olympia has been working on is evaluating and making sure that our cameras will be able to meet these new rules. As a manufacturer, we’re jumping out in front and making sure that we’re compliant to the new standards.

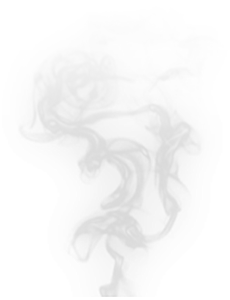

Detectable Gases

Most alkane and hydrocarbon gasses have an absorption band within the MWIR spectrum (3-5µm). Sierra-Olympia’s OGI cameras use a specially tuned bandpass filter in their dewar cold section to increase sensitivity for detection of absorbed energy from these gasses. The ability to visualize the gas is often specified as a temperature Δ against background, and detectability standards such as OOOO set thresholds for detectable ΔT. Under most conditions with most gasses, Sierra OGI cameras are able to identify gasses with 1° – 2° ΔT, well within OOOOb and OOOOa limits. Advanced image processing in Sierra-Olympia’s OGI cameras further enhance detectability so they can detect smaller leaks at further distances.

Benzene

Industry Applications

All of our products or cameras are considered components. We enable our partners to create tools for their own vision and specific needs. Our products are integrated it into something that may fly in the sky or travel on the ground, and are sometimes paired with other data collecting systems and software.

Extraction Sites

Integration for offshore and onshore oil and gas drilling or extraction sites. Keep the working environment safe and free from danger.

Pipelines

Integration for pipes, flanges connection seals, fuel lines and other equipment. Make sure transportation lines are leak free.

Downstream Locations

Integrations for refineries to help keep in line with strict environmental regulation and prevent costly legal fees.

THE VENTUS OGI WAS THE FIRST CAMERA ON THE MARKET WITH A HOT MID-WAVE INFRARED DETECTOR, IMPROVing low-swap and EXTENDing THE LIFE OF THE CAMERA.

JEFF LEAKE

(VP OF SALES)

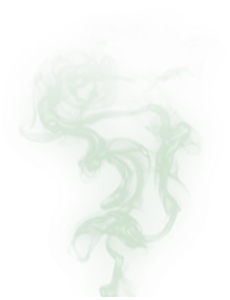

Gas Enhancement Mode

Gas enhancement mode (GEM) will colorize the leak, helping to spot dangerous conditions, so you can more efficiently run your facilities and keep people safe. Quickly addressing leaks will also save you money on equipment.